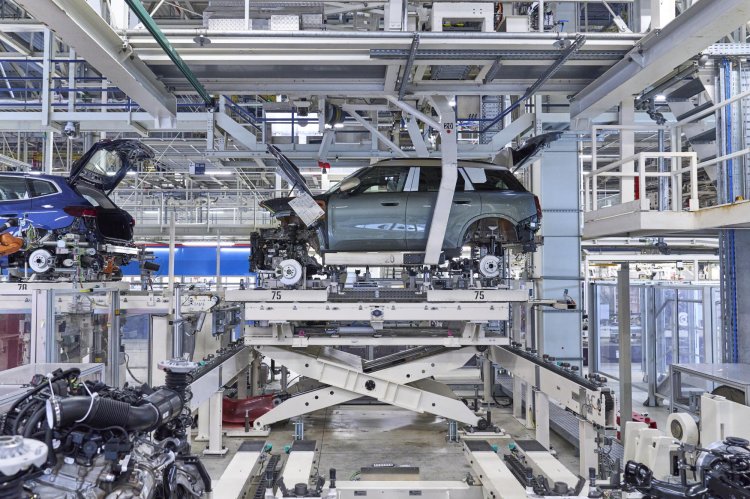

The start of MINI Countryman production marks a number of firsts and milestones for BMW Group Plant Leipzig: for the first time, a MINI model is being made in Germany – on the same production line as the BMW 1 Series and 2 Series. It’s all made possible by the plant’s flexible structures and development.

Over the last five years the BMW Group has invested €700 million to ready Leipzig for increased vehicle volumes and adapt it for MINI-specific requirements. By the end of 2024 the workforce in production will increase by over 900. In addition, the new MINI Countryman is a catalyst for innovations in sustainable production.

When it comes to production of the new MINI Countryman, the BMW Group is building on the skills and extreme flexibility of Plant Leipzig to forge new pathways in manufacturing. Seamlessly integrated into the production process, the MINI Countryman now rolls off the same assembly line as the BMW 1 Series, BMW 2 Series Gran Coupé and BMW 2 Series Active Tourer.

Thanks to its flexible assembly structures, Plant Leipzig is in a position to produce two brands with three different drives – combustion, plug-in-hybrid and fully electric – all on the same production line. The third-generation MINI Countryman will be available with a petrol, diesel or fully electric powertrain, with the high-voltage batteries for the MINI Countryman Electric also being made in Leipzig. It will reach dealerships on 17 February 2024.